Tantalum and niobium, tin ore is found in which state in Nigeria

Pingell granite placer type tantalum and niobium, tin ore is found in which state in Nigeria

Deposits of this type are mainly alluvial, while the landforms are mainly floodplains and newly formed riverbeds. The riverbed is mainly composed of a modern river channel, heart beach, side beach, and other river micro geomorphic forms. The lithology is mainly sand layer and sand gravel layer, the clay content is about 10%, and the thickness is small, mostly between 0.5-1.0m. Because the mainstream line of the river is constantly bent due to accumulation, which overlaps with the total forward movement and transverse circulation of the water flow, the modern riverbed continuously cuts the floodplain and overlaps it in the form of internal superposition. In some river sections, however, the content of niobium iron minerals is still higher than that of the boundary grade, which is one of the main metallogenic units in the area.

tin ore is found in which state in Nigeria

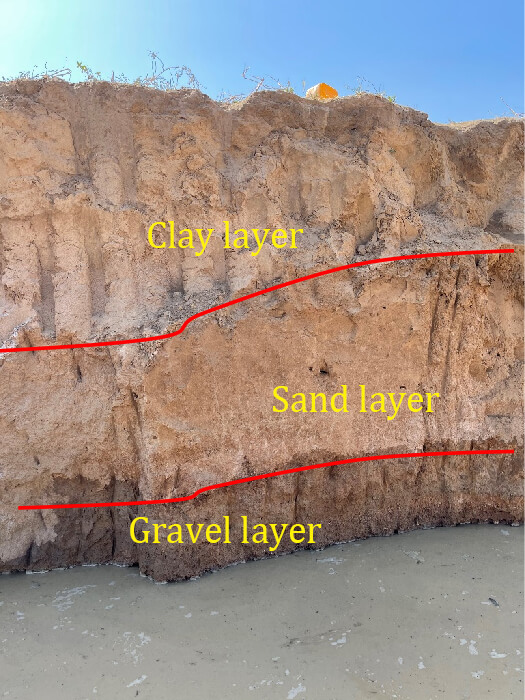

(1) Clay layer

The upper near surface clay layer is mainly grayish brown and grayish yellow, mainly composed of kaolinite, containing silty fine sand, with a thickness of more than 0.5m 5-5. Between 5m. The regional zoning characteristics of the clay layer in the middle and lower part are obvious. The clay layer is mainly cyan gray, mostly composed of kaolinite, with single component, dense lithology, good water resistance, thickness of 1-6m, and a small amount of silty fine sand in some parts.

(2) Sand layer

An important ore bearing horizon in the area is the sand layer. During the same sedimentary period, the particle size distribution from top to bottom is very obvious, mostly consisting of silty sand, silty fine sand, medium coarse sand, and containing some quartz fine gravel, slowly increasing as one descends. Sand is mainly composed of quartz, mostly more than 65%, in addition to weathered feldspar debris and clay minerals; Medium sorting, medium roundness, mostly subangular and subcircular; The thickness ranges from 0.3-5.0m, and can reach up to 6.0m. From south to north, weathered feldspar clasts gradually decrease in content, and its characteristics of rich weathered feldspar clasts reflect the sedimentary characteristics of the adjacent provenance area and the proximity of ore-forming clastic materials to this region.

(3) Gravel layer

It is one of the main ore-bearing horizons in the area, located at the bottom of the same sedimentary period, and its thickness is usually 0.5 mm 3-2. Between 4m. The proportion of each component constituting the gravel layer: clay mineral 15% – 25%, sand 25% – 45%, gravel 30% – 50%. Clay minerals are mostly kaolinite, sand is mainly quartz, gravel is mostly fine gravel, a small amount of medium gravel is found, gravel size is usually between 2-80mm, medium sphericity, high roundness, mostly in sub roundness, gravel is primarily quartz, followed by rock debris. The original rock lithology is mostly granite, quartz porphyry, altered rock, etc., and a small amount is weathered feldspar phenocryst debris. It varies greatly in composition, with high clay content and low gravel content in some places, and high sand content and low gravel content in others.

minerals found in Nigeria

A field investigation found that the exposed length of the surface ore body is about 5000m, the width is 50-500m, the average width is about 200m, and the thickness of the ore body is about 1m. The grade of the ore body is unknown. It is necessary to further carry out shallow well exploration and verification. It is reported that the cassiterite grade tested in the past was about 0.4kg/m3. The grade of the associated niobium is high, and the details are unknown.

minerals in Nigeria

Work Suggestion

Establish the gradation of the ore body scale and grade using deep-well engineering, using 100 * 100m project spacing, and identify the available reserves to ensure reliable resources for future development.